|

Français |

|

|

Printable version |

|

||||

|

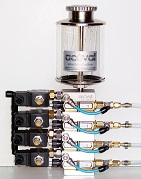

ECOPULS systems

|

| |||

|

ACOVAL microlubrication systems of the type PULS are instantaneous lubrication systems. They deliver an amount of liquid each time they are activated. They can be used:

In he case (1) where an amount of liquid is delivered without using compressed air to drive the liquid, it is important to take into account the superficial tension phenomenon.

Repercussion of the superficial tension phenomenon

| the amount of liquid delivered at a hole each time a micropump is activated is : | Natural behaviour | To extract the liquid each pulse | To spread the liquid out over time |

|---|---|---|---|

| bellow a drop | A drop falls down from time to time but not each time the micropump is activated | It's necessary:

| Use of compressed air and nozzles |

| equal to a drop | A drop falls down each time the micropump is activated | Use of compressed air and nozzles | |

| more than a drop | A drop falls down each time the micropump is activated. Other drops fall down from time to time. | Use of compressed air and nozzles (top) |

The driving duration and the time interval between two drives must allow an accurate working of micropumps.

In the case (2) where a nozzle focuses or sprays liquid, the driving duration of the system must be:

The time interval between two drives must be enough to allow a correct system initialisation.

ECOPULS systems are often used:

Typical samples concern cutting, stamping and high pace machining operations.

The user often want a system of type PULS to work at the same rate as his equipment (his press or his machine tool). It is often a mistake because:

So it is better to use a system of the type ECOFLUX or ACOFLUX with a lower speed. The gas spreads the liquid out all along the time.

These models without a cabinet generally include between one and six micropumps.

The liquid flow of each micropump is adjustable.

There is only one air flow setting or an air flow setting for each nozzle.

These systems are fitted with:

EP1E |

|

EP7E |

|

EP2E-2E |

|

EP4E-4E-V |

|

EP4E-3E |

|